Let’s learn about Renold Flexible Couplings PM with Dai Hong Phat, through the following article!

1. About Dai Hong Phat Corp – Renold UK

– Dai Hong Phat Corp is the official authorized representative of Renold UK in Vietnam. We provide genuine transmission shaft coupling solutions, meeting international standards, helping to optimize the performance and durability of machinery systems.

– Renold began in 1879, when Hans Renold bought a chain manufacturing company, inventing the bush roller chain the following year. Today, Renold specializes in manufacturing precision industrial chains, clutches, gears and couplings with global transmission solutions. The company serves many industries such as conveyors, machine manufacturing, transportation with durable transmission products and professional technical support.

– Renold PM Flexible Couplings products provided by Dai Hong Phat are 100% genuine imported, with full CO/CQ, meeting international quality standards.

2. Characteristics of Renold Flexible Couplings PM

– Manufacturer brand: Renold/England.

– The Renold Flexible Couplings PM is made of steel.

– Maximum torque: 7000 kNm.

– The driving flange, ranging from PM60 and including PM7000, is forged steel to BS970 grade 070 M55.

– The driving flange from PM90 to PM7000, and all internal and external components up to PM7000, are cast steel to BS 3100 grade A4.

– The rubber elements are fully encapsulated and individually encased with options for grade and hardness, with styrene-butadiene rubber with a hardness of 60 (SM60) being the standard. Rubber elements are loaded in compression.

– It protects and prevents controller failure under the influence of high torque passing through.

– Ensures continuous operation of the drilling machine in case of unfortunate rubber breakdown or damage.

– No lubrication or adjustment is required, resulting in low operating costs.

– Achieves low vibration loads in the transmission components by selecting optimal stiffness characteristics.

– Eliminates torque amplification by pre-compressing the rubber elements.

– Flexible Couplings PM allows for axial and radial misalignment between the driving and driven machinery.

View more product: Renold PM Elastomer Rings (Rubber Elements)

| FOR ANY INQUIRIES OR QUOTATION REQUESTS, PLEASE CONTACT: SALES DEPARTMENT HOTLINE: (+84) 0906 955 057 – EMAIL: INFO@DHP-CORP.COM.VN |

3. Applications of Renold Flexible Couplings PM

The Renold flexible coupling PM is specially designed for heavy-duty industrial applications, providing exceptional protection against severe impact loads and vibrations. The Renold PM range is used in industries such as metal manufacturing, mining and mineral processing, pumps, compressors, cranes and hoists, pulp and paper industry, and heavy-duty industrial applications in general.

View article: What is Flexible Shaft Coupling? Types of Flexible Shaft Couplings in 2025

4. Technical specifications of Renold PM Flexible Couplings

| Catalogue Renold PM Coupling |

Installation Renold PM Coupling |

||||||

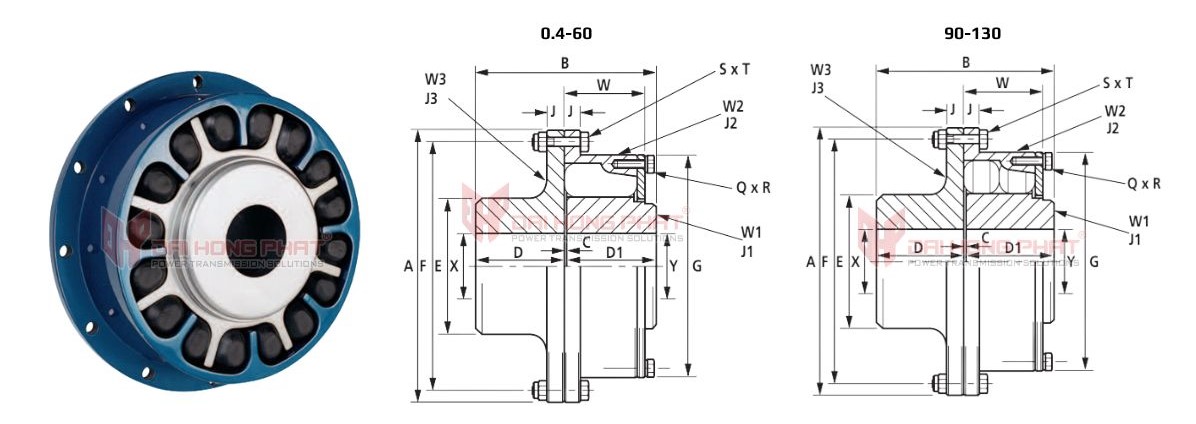

Technical drawing of Renold PM Flexible Coupling

| COUPLING SIZE | 0.4 | 0.7 | 1.3 | 3 | 6 | 8 | 12 | 18 | 27 | 40 | 60 | 90 | 130 | |||||||||||||||

| DIMENSIONS (mm) |

A | 161.9 | 187.3 | 215.9 | 260.3 | 260 | 302 | 338 | 392 | 440 | 490 | 568 | 638 | 728 | ||||||||||||||

| B | 103 | 110 | 130 | 143 | 175 | 193 | 221.5 | 254 | 290.5 | 329 | 377.5 | 432.5 | 487 | |||||||||||||||

| C | 1 | 2 | 2 | 3 | 3 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6.5 | 7 | |||||||||||||||

| D | 51 | 54 | 64 | 70 | 86 | 95 | 109 | 125 | 143 | 162 | 186 | 213 | 240 | |||||||||||||||

| D1 | 51 | 54 | 64 | 70 | 86 | 95 | 109 | 125 | 143 | 162 | 186 | 213 | 240 | |||||||||||||||

| E | 76 | 92 | 108 | 122 | 135 | 148 | 168 | 195 | 220 | 252 | 288 | 330 | 373 | |||||||||||||||

| F | 146 | 171.4 | 196.8 | 235 | 240 | 276 | 312 | 360 | 407 | 458 | 528 | 598 | 680 | |||||||||||||||

| G | 133 | 157 | 181 | 214.3 | 222 | 245 | 280 | 320 | 367 | 418 | 479 | 548 | 620 | |||||||||||||||

| J | 9.5 | 11 | 12 | 14.5 | 11 | 13.5 | 14 | 16 | 18.5 | 21 | 24 | 26.5 | 31 | |||||||||||||||

| Q | 5 | 5 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |||||||||||||||

| R | M8 | M8 | M8 | M8 | M8 | M10 | M12 | M16 | M16 | M16 | M20 | M20 | M24 | |||||||||||||||

| S | 8 | 8 | 8 | 8 | 12 | 12 | 12 | 12 | 12 | 16 | 12 | 16 | 16 | |||||||||||||||

| T | M8 | M8 | M8 | M8 | M8 | M12 | M12 | M16 | M16 | M16 | M20 | M20 | M24 | |||||||||||||||

| W | 36 | 39 | 46 | 60 | 81 | 89 | 102 | 118 | 134 | 152.7 | 175 | 200 | 226 | |||||||||||||||

| MAX. X & Y (4) | 41 | 51 | 64 | 73 | 85 | 95 | 109 | 125 | 143 | 162 | 186 | 213 | 240 | |||||||||||||||

| MIN. X (5) | 27 | 27 | 35 | 37 | 50 | 62 | 68 | 80 | 90 | 105 | 120 | 140 | 160 | |||||||||||||||

| MIN. Y | 27 | 27 | 37 | 40 | 50 | 55 | 65 | 70 | 85 | 105 | 110 | 140 | 160 | |||||||||||||||

| RUBBER ELEMENTS |

Per Cavity Per Coupling |

1 10 |

1 10 |

1 12 |

1 12 |

1 16 |

1 16 |

1 16 |

1 16 |

1 16 |

1 16 |

1 16 |

2 32 |

2 32 |

||||||||||||||

| MAXIMUM SPEED (rpm) (1) | 7200 | 6300 | 5400 | 4500 | 4480 | 3860 | 3450 | 2975 | 2650 | 2380 | 2050 | 1830 | 1600 | |||||||||||||||

| WEIGHT (3) (kg) |

W1 W2 W3 TOTAL |

1.9 2.0 2.8 6.7 |

2.8 2.9 4.3 10.0 |

4.5 4.6 6.6 15.7 |

6.9 6.0 10.0 22.9 |

8.9 6.55 10.84 26.3 |

11.62 10.92 15.14 37.7 |

17.74 15.86 21.24 54.8 |

27.0 24.59 33.03 84.6 |

40.18 35.34 47.80 123.3 |

59.5 50.47 69.32 179.3 |

89.45 77.80 104.63 271.9 |

132.0 111.96 151.78 395.7 |

191.11 165.24 222.39 578.7 |

||||||||||||||

| INERTIA (3) (kg m2) |

J1 J2 J3 |

0.002 0.006 0.005 |

0.004 0.014 0.013 |

0.008 0.019 0.025 |

0.018 0.049 0.05 |

0.026 0.072 0.058 |

0.050 0.149 0.116 |

0.101 0.273 0.194 |

0.203 0.560 0.406 |

0.392 1.041 0.748 |

0.756 1.898 1.345 |

1.491 3.867 2.719 |

2.872 7.188 4.955 |

5.330 13.680 9.565 |

||||||||||||||

| ALLOWABLE MISALIGNMENT (2) RADIAL (mm) AXIAL (mm) CONICAL (degree) |

0.8 0.8 0.5 |

0.8 1.2 0.5 |

0.8 1.2 0.5 |

1.2 1.2 0.5 |

1.5 1.25 0.5 |

1.6 1.5 0.5 |

1.6 1.75 0.5 |

1.6 2.0 0.5 |

1.9 2.25 0.5 |

2.1 2.5 0.5 |

2.4 2.75 0.5 |

2.8 3.25 0.5 |

3.3 3.5 0.5 |

|||||||||||||||

| COUPLING SIZE | 180 | 270 | 400 | 600 | 850 | 1200 | 2000 | 3500 | 4700 | 7000 | ||||||

| DIMENSIONS (mm) |

A | 798 | 925 | 1065 | 1195 | 1143 | 1320.8 | 1574.8 | 2006.6 | 2006.6 | 2006.6 | |||||

| B | 544 | 623 | 710.5 | 812 | 831 | 869 | 1035 | 1245 | 1447 | 1877 | ||||||

| C | 8 | 9 | 10.5 | 12 | 6.35 | 6.35 | 6.35 | 12.7 | 12.7 | 12.7 | ||||||

| D | 268 | 307 | 350 | 400 | 406 | 425 | 508 | 507 | 711 | 875 | ||||||

| D1 | 268 | 307 | 350 | 400 | 406 | 425 | 508 | 507 | 711 | 875 | ||||||

| E | 415 | 475 | 542 | 620 | 648 | 762 | 965 | 1016 | 1220 | 1370 | ||||||

| F | 750 | 865 | 992 | 1122 | 1066.8 | 1239.9 | 1473.2 | 1892.3 | 1892.3 | 1892.3 | ||||||

| J | 33.5 | 36 | 43 | 52 | 44.5 | 50.8 | 63.5 | 76 | 76 | 76 | ||||||

| Q | 12 | 12 | 12 | 12 | 20 | 20 | 20 | 24 | 24 | 24 | ||||||

| R | M24 | M30 | M36 | M36 | M30 | M30 | M36 | M36 | M36 | M36 | ||||||

| S | 20 | 20 | 20 | 24 | 20 | 20 | 20 | 24 | 24 | 24 | ||||||

| T | M24 | M30 | M36 | M36 | M36 | M36 | M45 | M48 | M48 | M48 | ||||||

| W | 252 | 288.5 | 328 | 376 | 425.5 | 444.5 | 514.4 | 520.7 | 643.5 | 1003.3 | ||||||

| MAX. X & Y (4) | 268 | 307 | 350 | 400 | 400 | 457 | 559 | 612 | 711 | 813 | ||||||

| MIN. X | 167 | 192 | 232 | 285 | 343 | 381 | 457 | 533 | 609 | 686 | ||||||

| MIN. Y | 170 | 195 | 235 | 285 | 343 | 381 | 457 | 533 | 609 | 686 | ||||||

| RUBBER ELEMENTS |

Per Cavity Per Coupling |

2 32 |

2 32 |

2 32 |

2 32 |

2 48 |

3 78 |

3 84 |

3 96 |

4 128 |

6 192 |

|||||

| MAXIMUM SPEED (rpm) (1) | 1460 | 1260 | 1090 | 975 | 1000 | 870 | 725 | 580 | 580 | 580 | ||||||

| WEIGHT (3) (kg) TOTAL |

W1 W2 W3 | 262.3 266.78 297.4 826.5 |

389.0 414.0 437.3 1240.3 |

562.4 633.4 651.2 1847 |

813.3 909.1 946.7 2669.1 |

1059.9 710.3 929.8 2700.0 |

1633.3 965.1 1388.8 3987.2 |

2594.6 1670.9 2631.4 6896.9 |

5263.3 2732.2 4185.5 12181.0 |

6450.8 3921.2 7196.1 17568.1 |

8644.4 4895.6 7742.9 21282.9 |

|||||

| INERTIA (3) (kg m2) |

J1 J2 J3 |

9.14 28.80 15.35 |

17.88 59.30 29.89 |

34.03 119.5 60.66 |

65.54 220.2 115.7 |

103.97 163.89 105.01 |

221.36 306.74 212.24 |

493.67 743.28 587.70 |

1653.41 2075.48 1466.3 |

2145.76 3056.46 2637.60 |

3063.85 3755.94 2927.67 |

|||||

| ALLOWABLE MISALIGNMENT (2) RADIAL (mm) AXIAL (mm) CONICAL (degree) |

3.5 4.0 0.5 |

3.9 4.5 0.5 |

4.6 5.25 0.5 |

5.2 6.0 0.5 |

2.8 3.2 0.5 |

3.3 3.2 0.5 |

3.3 4.8 0.5 |

3.3 6.3 0.5 |

3.3 6.3 0.5 |

3.3 6.3 0.5 |

||||||

5. Why choose Dai Hong Phat Corp?

– 100% genuine products imported directly from Renold UK.

– Protect customers from counterfeit goods and always provide full CO/CQ documents.

– Goods in stock, fast delivery nationwide 24/7.

– Free technical consultation and support for drawings, catalogs.

– Refined processing workshop to meet individual requirements.

—————-/—————–/—————–/—————–/—————–

With more than 15 years of experience, Dai Hong Phat Transmission Shaft Coupling is proud to be a trusted partner of hundreds of domestic and foreign enterprises.

Let us accompany your sustainable development!

DAI HONG PHAT ENGINEERING SERVICE TRADING MANUFACTURE COMPANY LIMITED

– Ho Chi Minh City Office: 22 Street 11, Khang Dien Residential Area, Duong Dinh Hoi Street, Phuoc Long Ward, Ho Chi Minh City.

– Hanoi Office: No. 14-15A, 7th Floor, Charmvit Building, No. 117 Tran Duy Hung, Thanh Xuan Ward, Hanoi City.

– Tel HCM: +84.28.22536631 – 22536632 – 66818587 | | Fax: 028.22536632

– Hotline: +84906.955.057 | – Email: info@dhp-corp.com.vn

– Website: https://en.daihongphat.asia/ – https://khopnoitruc.com/ – https://ringfeder.com.vn/