Let’s learn about Renold Welded Steel Conveyor Chains (Industrial Chains) with Dai Hong Phat, through the following article!

1. About Dai Hong Phat Corp – Renold UK

– Dai Hong Phat Corp is the official authorized representative of Renold UK in Vietnam. We provide genuine transmission shaft coupling solutions, meeting international standards, helping to optimize the performance and durability of machinery systems.

– Renold began in 1879, when Hans Renold bought a chain manufacturing company, inventing the bush roller chain the following year. Today, Renold specializes in manufacturing precision industrial chains, clutches, gears and couplings with global transmission solutions. The company serves many industries such as conveyors, machine manufacturing, transportation with durable transmission products and professional technical support.

– Renold Welded Steel Conveyor Industrial Chains products provided by Dai Hong Phat are 100% genuine imported, with full CO/CQ, meeting international quality standards.

Learn more about Other Renold Industrial Chains here

2. Characteristics of the Welded Steel Conveyor Chains:

– The Wedded Steel Conveyor Chain is manufactured by Renold/England.

– Typically features a turnbuckle link construction. The pins have a suitable press fit with the side plates, thereby eliminating unnecessary wear due to pin movement.

– Medium carbon grade steel is used for the pins and plates and can be heat-treated to provide increased strength and wear resistance.

– The bushings are made of carbon steel with a plated coating, which can be case-hardened.

– Precise interference fits of the pins in the side plates and single plates ground on the pin ends help prevent unnecessary wear due to pin movement.

– Holes are accurately drilled, and the assembly process ensures size control.

– The flexibility of the welded construction provides a wider range of accessory attachment options compared to what is typically provided for similar cast chains.

View more product “Waste Water Treatment Chain“

| FOR ANY INQUIRIES OR QUOTATION REQUESTS, PLEASE CONTACT: SALES DEPARTMENT HOTLINE: +84906 955 057 – EMAIL: INFO@DHP-CORP.COM.VN |

3. Applications of the Welded Steel Coneyor Chain:

The welded steel conveyor chains are widely used across industries for material handling purposes due to its durability and strength. It finds applications in automotive manufacturing, mining, agriculture, food processing, packaging, chemical plants, and waste management facilities. This versatile chain facilitates the transportation of various materials such as components, ores, crops, food products, chemicals, and waste, making it an essential component in industrial conveyor systems.

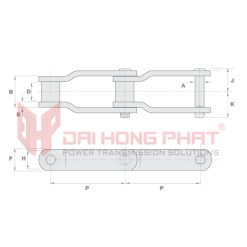

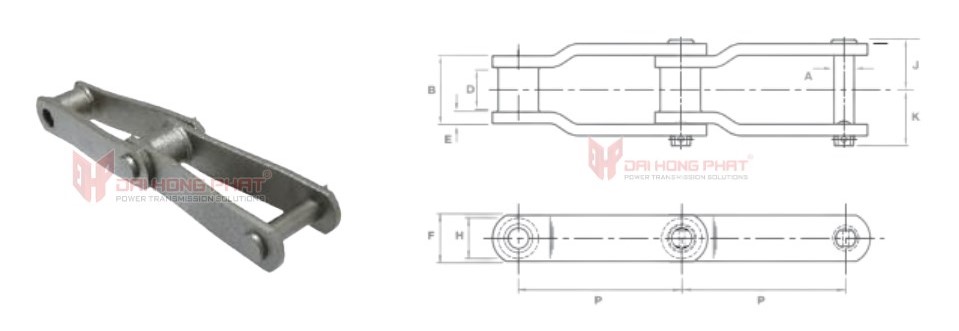

4. Technical drawing of the Welded Steel Conveyor Chains:

| Catalogue Steel Conveyor Chain |

Installation Steel Conveyor Chain |

||||||

| Chain No | Pitch mm | Pitch inch | Mass kg/m |

Average Ultimate Strength (Newtons) |

Pin Diameter | Sprocket Thickness MAX |

Plate Thickness | Plate Height | Bush Diameter | CL to Pin Head | CL to Pin End | Outside Width at Inner Plate |

| Permaweld W | ||||||||||||

| P | P | A | D | E | F | H | J | K | B | |||

| W-78 | 66.269 | 2.609 | 6.251 | 106762 | 12.700 | 28.575 | 6.350 | 28.575 | 22.225 | 36.116 | 40.084 | 50.800 |

| W-78P | 66.269 | 2.609 | 6.251 | 133452 | 12.700 | 28.575 | 6.350 | 28.575 | 22.225 | 36.116 | 40.081 | 50.800 |

| W-82 | 78.105 | 3.075 | 7.442 | 115658 | 14.288 | 31.750 | 6.350 | 31.750 | 26.988 | 38.497 | 43.259 | 57.150 |

| W-82P | 78.105 | 3.075 | 7.442 | 155694 | 14.288 | 31.750 | 6.350 | 31.750 | 26.988 | 38.506 | 43.256 | 57.150 |

| W-82XHD | 78.105 | 3.075 | 13.097 | 204626 | 19.050 | 31.750 | 9.525 | 38.100 | 34.925 | 45.641 | 53.578 | 63.500 |

| W-106 | 152.400 | 6.000 | 9.972 | 164591 | 19.050 | 41.275 | 9.525 | 38.100 | 34.925 | 49.609 | 56.753 | 71.438 |

| W-106P | 152.400 | 6.000 | 9.972 | 260231 | 19.050 | 41.275 | 9.525 | 38.100 | 34.925 | 49.606 | 56.744 | 71.450 |

| W-106HD | 152.400 | 6.000 | 12.204 | 222420 | 19.050 | 41.275 | 12.700 | 38.100 | 31.750 | 56.356 | 63.500 | 77.788 |

| W-110 | 152.400 | 6.000 | 9.674 | 204626 | 19.050 | 47.625 | 9.525 | 38.100 | 31.750 | 51.991 | 59.134 | 76.200 |

| W-110P | 152.400 | 6.000 | 9.674 | 266904 | 19.050 | 47.625 | 9.525 | 38.100 | 36.513 | 51.994 | 59.131 | 76.200 |

| W-111 | 120.900 | 4.760 | 12.204 | 204626 | 19.050 | 57.150 | 9.525 | 38.100 | 36.513 | 56.753 | 63.897 | 85.725 |

| W-111P | 120.900 | 4.760 | 12.204 | 266904 | 19.050 | 57.150 | 9.525 | 38.100 | 41.275 | 56.744 | 63.907 | 85.725 |

| W-124 | 101.600 | 4.000 | 12.353 | 204626 | 19.050 | 41.275 | 9.525 | 38.100 | 41.275 | 49.606 | 56.744 | 71.438 |

| W-124P | 101.600 | 4.000 | 12.353 | 266904 | 19.050 | 41.275 | 9.525 | 38.100 | 41.275 | 49.606 | 56.744 | 71.450 |

| W-124HD | 103.200 | 4.063 | 20.241 | 373665 | 22.225 | 41.275 | 12.700 | 50.800 | 41.275 | 55.959 | 62.706 | 76.200 |

| W-124HDP | 103.200 | 4.063 | 20.241 | 400356 | 22.225 | 41.275 | 12.700 | 50.800 | 41.275 | 55.956 | 62.713 | 76.200 |

| W-132 | 153.670 | 6.050 | 19.497 | 373665 | 25.400 | 73.025 | 12.700 | 50.800 | 41.275 | 74.216 | 82.550 | 111.125 |

| W-132P | 153.670 | 6.050 | 19.497 | 444840 | 25.400 | 73.025 | 12.700 | 50.800 | 41.275 | 74.219 | 82.550 | 111.125 |

| W-132HD | 153.670 | 6.050 | 22.920 | 467082 | 25.400 | 73.025 | 15.875 | 50.800 | 41.275 | 80.566 | 88.900 | 117.475 |

| W-132HDP | 153.670 | 6.050 | 22.920 | 533808 | 25.400 | 73.025 | 15.875 | 50.800 | 41.275 | 80.569 | 88.900 | 117.475 |

| W-134 | 103.200 | 4.063 | 24.855 | 458185 | 25.400 | 41.275 | 12.700 | 63.500 | 41.275 | 56.744 | 62.706 | 76.200 |

| W-134P | 103.200 | 4.063 | 24.855 | 498221 | 25.400 | 41.275 | 12.700 | 63.500 | 41.275 | 56.744 | 62.713 | 76.200 |

| WS-150 | 153.670 | 6.050 | 23.515 | 373665 | 25.400 | 73.025 | 12.700 | 63.500 | 44.450 | 74.219 | 82.550 | 111.125 |

| WS-150P | 153.670 | 6.050 | 23.515 | 444840 | 25.400 | 73.025 | 12.700 | 63.500 | 44.450 | 74.219 | 82.550 | 111.125 |

| WS-157 | 153.670 | 6.050 | 29.022 | 556050 | 28.575 | 69.850 | 15.875 | 63.500 | 44.450 | 80.963 | 92.075 | 117.475 |

| WS-157P | 153.670 | 6.050 | 29.022 | 622776 | 28.575 | 69.850 | 15.875 | 63.500 | 44.450 | 80.975 | 92.075 | 117.475 |

| W-182 | 78.105 | 3.075 | 12.353 | 204626 | 19.050 | 28.575 | 9.525 | 38.100 | 34.925 | 42.466 | 50.403 | 57.150 |

| WS-784 | 101.600 | 4.000 | 4.911 | 106762 | 12.700 | 28.575 | 6.350 | 28.575 | 22.225 | 36.119 | 40.081 | 50.800 |

| WS-784P | 101.600 | 4.000 | 4.911 | 133452 | 12.700 | 28.575 | 6.350 | 28.575 | 22.225 | 36.119 | 40.081 | 50.800 |

| WS-855PB | 153.670 | 6.050 | 27.534 | 667260 | 28.575 | 69.850 | 14.288 | 63.500 | 44.450 | 76.994 | 89.694 | 112.713 |

| Chain No | Pitch mm | Pitch inch | Mass kg/m |

Average Ultimate Strength (Newtons) |

Pin Diameter | Sprocket Thickness MAX |

Plate Thickness | Plate Height | CL to Pin Head | CL to Pin End | Outside Width at Inner Plate |

| Permaweld WD | |||||||||||

| P | P | A | D | E | F | J | K | X | |||

| WD-102 | 127.0 | 5.0 | 15.478 | 226868 | 19.050 | 161.925 | 9.525 | 38.100 | 113.903 | 121.047 | 196.850 |

| WD-102P | 127.0 | 5.0 | 15.478 | 266904 | 19.050 | 161.925 | 9.525 | 38.100 | 113.894 | 121.057 | 196.850 |

| WD-104 | 76.2 | 3.0 | 11.758 | 226868 | 19.050 | 104.775 | 9.525 | 38.100 | 83.741 | 90.885 | 136.525 |

| WD-104P | 76.2 | 3.0 | 11.758 | 266904 | 19.050 | 104.775 | 9.525 | 38.100 | 83.744 | 90.881 | 136.525 |

| WD-110 | 76.2 | 3.0 | 16.074 | 226868 | 19.050 | 228.600 | 9.525 | 38.100 | 147.241 | 154.385 | 263.526 |

| WD-110P | 76.2 | 3.0 | 16.074 | 266904 | 19.050 | 228.600 | 9.525 | 38.100 | 147.244 | 154.382 | 263.526 |

| WD-112 | 203.2 | 8.0 | 13.544 | 226868 | 19.050 | 228.600 | 9.525 | 38.100 | 147.241 | 154.385 | 263.526 |

| WD-112P | 203.2 | 8.0 | 13.544 | 266904 | 19.050 | 228.600 | 9.525 | 38.100 | 147.244 | 154.382 | 263.526 |

| WD-116 | 203.2 | 8.0 | 20.985 | 226868 | 19.050 | 330.201 | 9.525 | 44.450 | 194.866 | 202.010 | 358.776 |

| WD-116P | 203.2 | 8.0 | 20.985 | 306940 | 19.050 | 330.201 | 9.525 | 44.450 | 194.869 | 202.007 | 358.776 |

| WD-120 | 152.4 | 6.0 | 26.939 | 311388 | 22.225 | 222.250 | 12.700 | 50.800 | 150.019 | 156.369 | 260.351 |

| WD-120P | 152.4 | 6.0 | 26.939 | 400356 | 22.225 | 222.250 | 12.700 | 50.800 | 150.013 | 156.363 | 260.351 |

| WD-122 | 203.2 | 8.0 | 22.771 | 311388 | 22.225 | 222.250 | 12.700 | 50.800 | 150.013 | 156.369 | 260.351 |

| WD-122P | 203.2 | 8.0 | 22.771 | 400356 | 22.225 | 222.250 | 12.700 | 50.800 | 150.013 | 156.363 | 260.351 |

| WD-480 | 203.2 | 8.0 | 25.450 | 311388 | 22.225 | 282.576 | 12.700 | 50.800 | 181.769 | 188.119 | 323.851 |

| WD-480P | 203.2 | 8.0 | 25.450 | 400356 | 22.225 | 282.576 | 12.700 | 50.800 | 181.763 | 188.113 | 323.851 |

| WD-480HP | 203.2 | 8.0 | 27.980 | 449288 | 25.400 | 282.576 | 12.700 | 50.800 | 181.763 | 188.113 | 323.851 |

| WD-480XHD | 203.2 | 8.0 | 31.255 | 378114 | 25.400 | 282.576 | 15.875 | 50.800 | 188.119 | 194.469 | 330.201 |

| WD-480XDHP | 203.2 | 8.0 | 31.255 | 542705 | 25.400 | 282.576 | 15.875 | 50.800 | 188.113 | 194.463 | 330.201 |

5. Why choose Dai Hong Phat Corp?

100% genuine products imported directly from Renold UK.

Protect customers from counterfeit goods and always provide full CO/CQ documents.

Goods in stock, fast delivery nationwide 24/7.

Free technical consultation and support for drawings, catalogs.

Refined processing workshop to meet individual requirements.

—————-/—————–/—————–/—————–/—————–

With more than 15 years of experience, Dai Hong Phat Shaft Coupling is proud to be a trusted partner of hundreds of domestic and foreign enterprises.

Let us accompany your sustainable development!

DAI HONG PHAT TECHNICAL PRODUCTION TRADING SERVICES CO., LTD

– Ho Chi Minh City Office: 22 Street 11, Khang Dien Residential Area, Duong Dinh Hoi Street, Phuoc Long Ward, Ho Chi Minh City.

– Hanoi Office: No. 14-15A, 7th Floor, Charmvit Building, No. 117 Tran Duy Hung, Thanh Xuan Ward, Hanoi City.

– Tel HCM: +84.28.22536631 – 22536632 – 66818587 | | Fax: 028.22536632

– Hotline: 0906.955.057 | – Email: info@dhp-corp.com.vn

– Website: https://en.daihongphat.asia/ – https://khopnoitruc.com/ – https://ringfeder.com.vn/