Let’s learn about JAC Gear Couplings GS/GSL with Dai Hong Phat through the following article!

1. About Dai Hong Phat Corp – JAC Korea

– Dai Hong Phat Corp is the official authorized representative of JAC Korea in Vietnam. We provide genuine drive shaft coupling solutions that meet international standards, helping to optimize the performance and durability of machinery systems.

– JAC was established in 1989 as the main coupling supplier for POSCO Steel Corporation in Korea. With more than 30 years of development, JAC has continuously innovated technology, expanded products, and met diverse global needs.

– JAC GS/GSL Gear Couplings products supplied by Dai Hong Phat are 100% genuine imports, with full CO/CQ, meeting international quality standards.

View more: Other JAC Gear Couplings

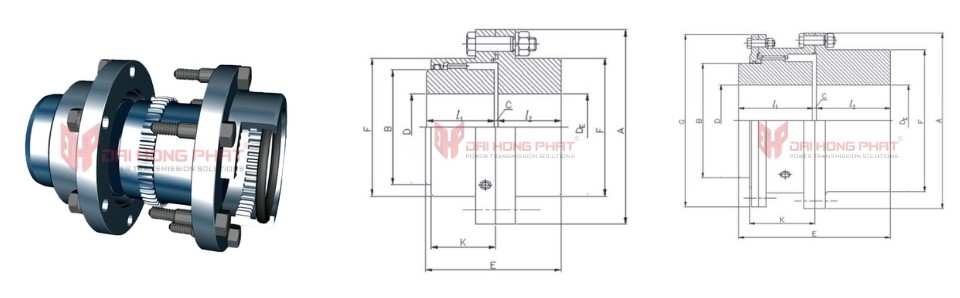

2. Characteristics of JAC Gear Couplings GS/GSL

– Manufacturer brand: JAC/Korea.

– They feature small and lightweight gears.

– The hub teeth are designed with a curved profile.

– Both sliding parts have grooves, making them easy to install and preventing grease leakage.

– These high-quality standard steel gear couplings meet KS and JIS standards.

– The Korean-standard steel gear couplings are designed to deliver high performance using the best techniques. With the ability to handle heavy loads, they are smaller and lighter than any other couplings. Noise and vibration are minimal even at high operating speeds.

View more product: Gear Couplings Type GD/GDL

| FOR ANY INQUIRIES OR QUOTATION REQUESTS, PLEASE CONTACT: SALES DEPARTMENT HOTLINE: +84906 955 057 – EMAIL: INFO@DHP-CORP.COM.VN |

3. Applications of JAC Gear Couplings GS/GSL

Gear shaft couplings Type GS/GSL are widely used across various professional industrial fields to transmit extremely high torque from one shaft to another. The JAC GS/GSL gear couplings include applications such as direct drive systems for conveyors, machine combinations, machinery, or rolling tables.

View more article: What is Flexible Shaft Coupling? Types of Flexible Shaft Couplings in 2025

4. Technical specificatiobns of the JAC GS/GSL Gear Coupling

| Catalogue JAC GS/GSL Gear Couplings |

Installation JAC GS/GSL Gear Couplings |

||||||

| Model | Torque rating (kgf.m) |

max. speed (rpm) |

Dimensions(mm) | grease Q`ty (kg) |

weight (kg) |

||||||||||

| Bore D (min /max) |

Bore DE (min /max) |

A | E | ℓ1 | ℓ2 |

B

|

F

|

K

|

G

|

C

|

|||||

|

GS 10

|

85.9

|

8000

|

13 / 48

|

13 / 60

|

116

|

87

|

43

|

40

|

69

|

84

|

39

|

–

|

4

|

0.02

|

4.5

|

|

GS 15

|

193.4

|

6500

|

19 / 60

|

19 / 75

|

152

|

99

|

49

|

46

|

86

|

105

|

48

|

–

|

4

|

0.04

|

9.1

|

|

GS 20

|

358.1

|

5600

|

25 / 73

|

25 / 92

|

178

|

124

|

62

|

58

|

105

|

126

|

59

|

–

|

4

|

0.07

|

15.9

|

|

GS 25

|

644.6

|

5000

|

32 / 92

|

32 / 111

|

213

|

156

|

77

|

74

|

131

|

155

|

72

|

–

|

5

|

0.12

|

27.2

|

|

GS 30

|

1074.3

|

4000

|

38 / 105

|

38 / 130

|

240

|

184

|

91

|

88

|

152

|

180

|

84

|

–

|

5

|

0.18

|

43.1

|

|

GS 35

|

1647.3

|

3900

|

51 / 124

|

51 / 149

|

279

|

213.5

|

106

|

102

|

178

|

211

|

98

|

–

|

5.5

|

0.27

|

61.2

|

|

GS 40

|

2506.7

|

3600

|

64 / 146

|

64 / 171

|

318

|

243

|

121

|

115

|

210

|

245

|

111

|

–

|

7

|

0.47

|

99.8

|

|

GS 45

|

3437.8/p>

|

3200

|

76 / 165

|

76 / 194

|

346

|

274

|

135

|

131

|

235

|

274

|

123

|

–

|

8

|

0.57

|

136.1

|

|

GS 50

|

4653.3

|

2900

|

89 / 178

|

89 / 222

|

389

|

309

|

153

|

147

|

254

|

306

|

141

|

–

|

9

|

0.91

|

195

|

|

GS 55

|

6087.7

|

2650

|

102 / 197

|

102 / 248

|

425

|

350

|

168

|

173

|

279

|

334

|

158

|

–

|

9

|

1.13

|

263.1

|

|

GS 60

|

7878.2

|

2450

|

114 / 222

|

114 / 267

|

457

|

384

|

188

|

186

|

305

|

366

|

169

|

–

|

10

|

1.7

|

324.3

|

|

GSL 70

|

11459.2

|

2150

|

89 / 254

|

89 / 305

|

527

|

454

|

221

|

220

|

343

|

–

|

196

|

517

|

13

|

2.27

|

508

|

|

GSL 80

|

15040.2

|

1750

|

102 / 279

|

102 / 343

|

591

|

511

|

249

|

249

|

356

|

–

|

243

|

572

|

13

|

4.99

|

698.5

|

|

GSL 90

|

20411.7

|

1550

|

114 / 305

|

114 / 381

|

660

|

566

|

276

|

276

|

394

|

–

|

265

|

641

|

14

|

6.35

|

984.5

|

|

GSL 100

|

28648

|

1450

|

127 / 343

|

127 / 406

|

711

|

626

|

305

|

305

|

445

|

–

|

294

|

699

|

16

|

7.71

|

1251.9

|

|

GSL 110

|

39394

|

1330

|

140 / 387

|

140 / 445

|

775

|

682

|

333

|

333

|

495

|

–

|

322

|

749

|

16

|

9.07

|

1637.5

|

|

GSL 120

|

50134

|

1200

|

150 / 425

|

150 / 495

|

838

|

719

|

353

|

353

|

546

|

–

|

341

|

826

|

16

|

10.89

|

2077.5

|

5. Why choose Dai Hong Phat Corp?

– 100% genuine products imported directly from JAC Korea.

– Protect customers from counterfeit goods and always provide full CO/CQ documents.

– Goods in stock, fast delivery nationwide 24/7.

– Free technical consultation and support for drawings, catalogs.

– Refined processing workshop to meet individual requirements.

—————-/—————–/—————–/—————–/—————–

With more than 15 years of experience, Dai Hong Phat Transmission Shaft Coupling is proud to be a trusted partner of hundreds of domestic and foreign enterprises.

Let us accompany your sustainable development!

DAI HONG PHAT ENGINEERING SERVICE TRADING MANUFACTURE COMPANY LIMITED

– Ho Chi Minh City Office: 22 Street 11, Khang Dien Residential Area, Duong Dinh Hoi Street, Phuoc Long Ward, Ho Chi Minh City.

– Hanoi Office: No. 14-15A, 7th Floor, Charmvit Building, No. 117 Tran Duy Hung, Thanh Xuan Ward, Hanoi City.

– Tel HCM: +84.28.22536631 – 22536632 – 66818587 | | Fax: 028.22536632

– Hotline: +84906.955.057 | – Email: info@dhp-corp.com.vn

– Website: https://en.daihongphat.asia/ – https://khopnoitruc.com/ – https://ringfeder.com.vn/