Let’s learn about Cross+Morse Flexible Couplings KE (HRC) with Dai Hong Phat, through the following article!

1. About Dai Hong Phat Corp – Cross+Morse UK

– Dai Hong Phat Corp is the official authorized representative of Cross+Morse UK in Vietnam. We provide genuine transmission shaft coupling solutions, meeting international standards, helping to optimize the performance and durability of machinery systems.

– Cross+Morse, established in 1984 in the UK. With a history of more than 100 years of development, is a leading supplier of power transmission solutions. Products such as industrial chains, sprockets, transmission couplings, and belts. From its headquarters in Birmingham, UK, Cross+Morse continues to maintain its global position in quality and reputation in the industry.

– The Cross+Morse Flexible Couplings KE (HRC) Series product supplied by Dai Hong Phat is 100% genuine imported, with full CO/CQ, meeting international quality standards.

2. Characteristics of Flexible Couplings KE (HRC)

– Manufacturer brand: Cross Morse/England.

– They come in 8 basic sizes.

– They can handle torque loads up to 3300 Nm.

– Available with either parallel keyway or tapered bushing bore.

– The gear teeth are cast in Pebax R Polyether.

– The gear ring cushions are made with maximum twist.

– Operates in temperatures ranging from -40°C to +85°C.

– The KE flexible couplings provide positive power transmission between shafts, combined with the ability to accommodate moderate misalignment. These couplings are designed to transmit torque equivalent to the capabilities of commercially available shaft sizes.

– The KE (HRC) couplings are designed to transmit torque equivalent to the capabilities of commercially available shaft sizes. Along with parallel keyway or tapered bushing bore, these couplings can be quickly and easily mounted on externally machined flanges allowing for simple alignment with just a straight edge.

– The gear teeth of the KE elastomeric jaw couplings are cast in Pebax R Polyether which is oil-resistant, partially resistant to chemicals, and has low moisture absorption rates. The maximum twist gear ring cushions effectively reduce operational vibrations and shock loads transmission.

View specification: Cross+Morse Elastomer Rings KE (HRC)

| FOR ANY INQUIRIES OR QUOTATION REQUESTS, PLEASE CONTACT: SALES DEPARTMENT HOTLINE: +84 906 955 057 – EMAIL: INFO@DHP-CORP.COM.VN |

3. Applications of Cross+Morse Flexible Couplings KE (HRC)

KE (HRC) Series Flexible Couplings are commonly used in industrial machinery such as agitators, beer brewing machines, centrifugal blowers and compressors, conveyors, pumps and centrifugal fans, generators, wastewater treatment equipment, and more.

4. Technical specifications of Flexible Couplings KE (HRC)

| Catalogue KE (HRC) Coupling |

Installation KE (HRC) Coupling |

||||||

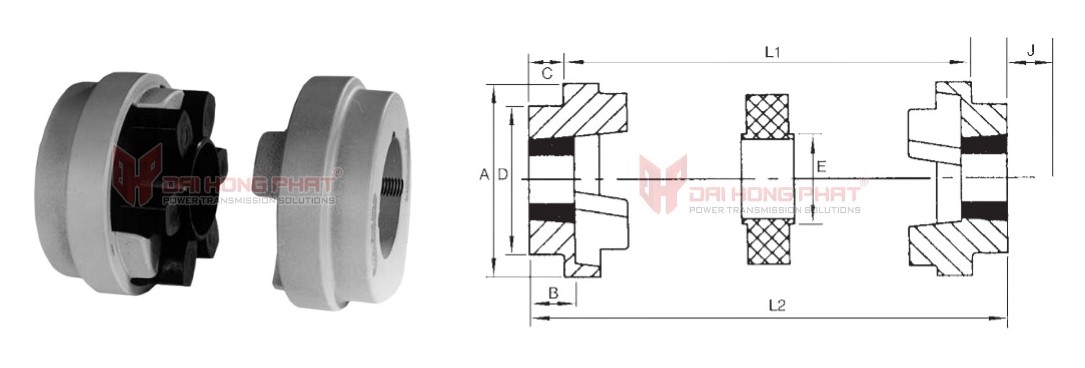

Technical drawing of KE (HRC) elastomeric jaw couplings

| Coupling No. | Nominal Torque (Nm) | Max Torque (Nm) | Max Speed (rpm) | Angular Misalignment (°) | Radial (mm) | Axial (mm) | Bush Size | Max Bore (mm) – Taper | Inertia Taper (kg·cm²) | Weight Taper (kg) | Min Bore (mm) – Solid | Max Bore (mm) – Solid | Inertia Solid (kg·cm²) | Weight Solid (kg) |

| HRC7 | 33 | 73 | 7700 | 1.0 | 0.3 | +0.2 | 1008 | 25 | 8.5 | 1.0 | 10 | 32 | 7.8 | 1.1 |

| HRC9 | 84 | 185 | 6300 | 1.0 | 0.3 | +0.5 | 1210 | 28 | 11.5 | 1.7 | 10 | 38 | 10.8 | 1.7 |

| HRC11 | 168 | 370 | 6300 | 1.0 | 0.3 | +0.6 | 1610 | 42 | 40 | 5.0 | 10 | 48 | 34.4 | 4.2 |

| HRC13 | 331 | 725 | 4100 | 1.0 | 0.4 | +0.8 | 1610 | 42 | 55 | 5.5 | 22 | 55 | 85 | 6.3 |

| HRC15 | 630 | 1490 | 3600 | 1.0 | 0.4 | +0.9 | 2012 | 50 | 181 | 7.1 | 28 | 65 | 211 | 9.5 |

| HRC18 | 998 | 3000 | 3000 | 1.0 | 0.4 | +1.1 | 2517 | 65 | 434 | 16.6 | 28 | 85 | 480 | 15.0 |

| HRC23 | 2100 | 4800 | 2600 | 1.0 | 0.5 | +1.3 | 3020 | 75 | 1207 | 26.0 | 48 | 95 | 1405 | 28.0 |

| HRC28 | 3300 | 7000 | 2200 | 1.0 | 0.5 | +1.7 | 3525 | 90 | 4465 | 50.0 | 63 | 130 | 5479 | 63.0 |

5. Why choose Dai Hong Phat Corp?

– 100% genuine products imported directly from Cross+Morse UK.

– Protect customers from counterfeit goods and always provide full CO/CQ documents.

– Goods in stock, fast delivery nationwide 24/7.

– Free technical consultation and support for drawings, catalogs.

– Refined processing workshop to meet individual requirements.

—————-/—————–/—————–/—————–/—————–

With more than 15 years of experience, Dai Hong Phat Transmission Shaft Coupling is proud to be a trusted partner of hundreds of domestic and foreign enterprises.

Let us accompany your sustainable development!

DAI HONG PHAT ENGINEERING SERVICE TRADING MANUFACTURE COMPANY LIMITED

– Ho Chi Minh City Office: 22 Street 11, Khang Dien Residential Area, Duong Dinh Hoi Street, Phuoc Long Ward, Ho Chi Minh City.

– Hanoi Office: No. 14-15A, 7th Floor, Charmvit Building, No. 117 Tran Duy Hung, Thanh Xuan Ward, Hanoi City.

– Tel HCM: +84.28.22536631 – 22536632 – 66818587 | | Fax: 028.22536632

– Hotline: +84906.955.057 | – Email: info@dhp-corp.com.vn

– Website: https://en.daihongphat.asia/ – https://khopnoitruc.com/ – https://ringfeder.com.vn/