1. Dai Hong Phat Corp. is the exclusive distributor of Renold Transmission Drive Chain across Vietnam:

– Renold, established since 1864, unified its manufacturing facilities in the United Kingdom into its current base in Cardiff by 2017. Renold is renowned in over 23 countries worldwide.

– We at Dai Hong Phat Corp collaborate with Renold, an esteemed manufacturer of high-quality power transmission equipment from England.

– As an importer and distributor, Dai Hong Phat Corp. supplies all Renold conveyor chains, ensuring they are 100% genuine, throughout Vietnam.

– With over 10 years of reputation, Dai Hong Phat guarantees customers genuine Standard Conveyor Chain of the highest quality and the best prices on the market.

2. Characteristics of the Standard Conveyor Chain:

– Standard Conveyor Chain is manufactured by Renold/England.

– Manufactured to ISO standards that cannot be substituted for BS or DIN standard chains.

– Maximum chain strength and wear resistance are achieved by closely controlling material specifications and using modern heat treatment processes.

– The overall consistent tolerance of Renold chains makes it ideal for transporting systems requiring precise interlinking in multi-strand conveyor layouts.

– Breaking loads exceed minimum international standards.

View more product “Heavy Duty Drag Chain“

| FOR ANY INQUIRIES OR QUOTATION REQUESTS, PLEASE CONTACT: SALES DEPARTMENT HOTLINE: (+84) 0906 955 057 – EMAIL: INFO@DHP-CORP.COM.VN |

3. Aplications of the Standard Conveyor Chain:

Standard Conveyor Chain is better suited for conveyor applications selected based on ultimate tensile strength (breaking load). Each chain has the same dimensions as its regular counterpart. Most of these applications utilize cable-type conveyor systems with long pitch chain discs. Such systems sometimes move slowly with light or no shock loads.

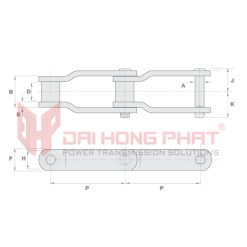

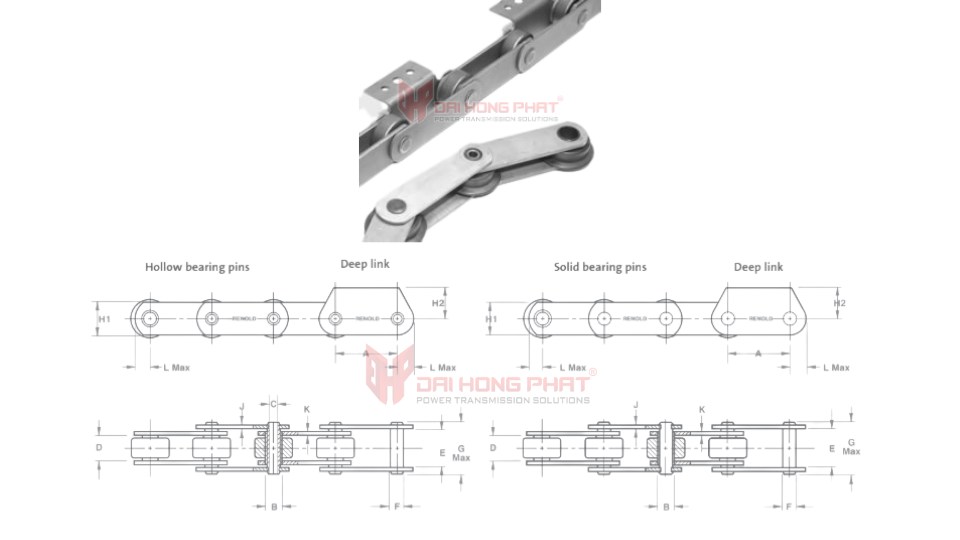

4. Technical drawing of the Standard Conveyor Chain:

| Catalogue Renold Standard Chain |

Installation Renold Standard Chain |

||||||

Standard Conveyor Chain

BS 4116 Part 4

| Breaking Load | B.S Series Ref |

Pitch Inch | Pitch Inch | Pitch mm | Pitch mm | Hollow Bearing Pin Bore Diam | Inside Width Inner | Inside Width Outer | Height | Width Outer | Width Inner | Head | |

| lb/f MIN |

(Newtons) MIN |

MIN | MAX | MIN | MAX | MIN | MIN | MIN | MAX | ||||

| Hollow Bearing Pin | |||||||||||||

| A | A | A | A | C | D | E | H2 | J | K | L | |||

| 4500 | 20000 | 2H020 | 1.5 | 3.0 | 38.1 | 76.2 | 6.6 | 12.7 | 17.8 | – | 1.8 | 2.3 | 11.4 |

| 6000 | 27000 | 3H027 | 1.5 | 6.0 | 38.1 | 152.4 | 10.1 | 15.0 | 25.4 | 26.0 | 3.8 | 3.8 | 15.0 |

| 12000 | 54000 | 4H054 | 2.0 | 9.0 | 50.8 | 228.6 | 13.2 | 19.0 | 32.5 | 32.0 | 3.8 | 5.1 | 22.1 |

| 24000 | 107000 | 5H107 | 3.5 | 12.0 | 88.9 | 304.8 | 20.1 | 25.4 | 43.0 | 45.0 | 5.1 | 7.1 | 29.7 |

| 36000 | 160000 | 6H160 | 5.0 | 18.0 | 127.0 | 457.2 | 23.1 | 38.1 | 59.0 | – | 7.6 | 8.9 | 34.8 |

| Solid Bearing Pin | |||||||||||||

| A | A | A | A | C | D | E | H2 | J | K | L | |||

| 3000 | 13000 | 1S013 | 1.0 | 4.5 | 25.4 | 114.3 | – | 11.7 | 16.0 | 16.0 | 1.8 | 1.8 | 11.4 |

| 7500 | 33000 | 3S033 | 1.5 | 6.0 | 38.1 | 152.4 | – | 15.0 | 25.4 | 26.0 | 3.8 | 3.8 | 15.0 |

| 15000 | 67000 | 4S067 | 2.0 | 9.0 | 50.8 | 228.6 | – | 19.0 | 32.5 | 32.0 | 3.8 | 5.1 | 22.1 |

| 30000 | 134000 | 5S134 | 3.5 | 12.0 | 88.9 | 304.8 | – | 25.4 | 43.0 | 45.0 | 5.1 | 7.1 | 29.7 |

| 45000 | 200000 | 6S200 | 5.0 | 18.0 | 127.0 | 457.2 | – | 38.1 | 59.0 | – | 7.6 | 8.9 | 34.8 |

| 60000 | 267000 | 7S267 | 6.0 | 18.0 | 152.4 | 457.2 | – | 38.1 | 59.0 | – | 7.6 | 8.9 | 34.8 |

| 90000 | 400000 | 8S400 | 6.0 | 24.0 | 152.4 | 609.6 | – | 38.1 | 66.3 | – | 10.0 | 13.0 | 35.8 |

Conveyor Chain

ISO 1977 Specification

| Chain No | Breaking Load | Pitch | Pitch | Bush Diam. | Hollow Bearing Pin Bore Diam. | Inside Width Inner | Inside Width Outer | Pin Diam. | Pin Length | Plate Width Outer | Plate Width Inner | Head |

| (Newtons) MIN |

MIN | MAX | MAX | MIN | MIN | MIN | MAX | MAX | MAX | |||

| Hollow Bearing Pin | ||||||||||||

| A | A | B | C | D | E | F | G | J | K | L | ||

| MC56 | 56000 | 80 | 250 | 21.0 | 10.2 | 24.0 | 33.7 | 15.5 | 46.5 | 4.0 | 4.0 | 19.4 |

| MC112 | 112000 | 100 | 315 | 29.0 | 14.3 | 32.0 | 45.7 | 22.0 | 63.0 | 6.0 | 6.0 | 27.3 |

| MC224 | 224000 | 160 | 500 | 41.0 | 20.3 | 43.0 | 60.8 | 31.0 | 83.0 | 8.0 | 8.0 | 37.8 |

| Solid Bearing Pin | ||||||||||||

| A | A | B | C | D | E | F | G | J | K | L | ||

| M40 | 40000 | 63 | 250 | 12.5 | – | 20.0 | 28.3 | 8.5 | 41.0 | 3.5 | 3.5 | 15.0 |

| M56 | 56000 | 63 | 250 | 15.0 | – | 24.0 | 33.3 | 10.0 | 47.0 | 4.0 | 4.0 | 17.5 |

| M80 | 80000 | 80 | 315 | 18.0 | – | 28.0 | 39.4 | 12.0 | 54.6 | 5.0 | 5.0 | 20.2 |

| M112 | 112000 | 80 | 400 | 21.0 | – | 32.0 | 45.5 | 15.0 | 60.6 | 5.0 | 6.0 | 23.0 |

| M160 | 160000 | 100 | 500 | 25.0 | – | 37.0 | 52.5 | 18.0 | 72.6 | 6.0 | 7.0 | 29.0 |

| M224 | 224000 | 125 | 630 | 30.0 | – | 43.0 | 60.6 | 21.0 | 84.0 | 6.0 | 8.0 | 35.0 |

| M315 | 315000 | 160 | 630 | 36.0 | – | 48.0 | 70.7 | 25.0 | 97.0 | 8.0 | 10.0 | 38.1 |

| M450 | 450000 | 200 | 800 | 42.0 | – | 56.0 | 82.8 | 30.0 | 114.0 | 10.0 | 12.0 | 43.4 |

| M630 | 630000 | 250 | 1000 | 50.0 | – | 66.0 | 97.0 | 36.0 | 133.0 | 14.0 | 14.0 | 54.1 |

| M900 | 900000 | 250 | 1000 | 60.0 | – | 78.0 | 113.0 | 44.0 | 153.0 | 16.0 | 16.0 | 64.7 |

5. Why choose Dai Hong Phat as the supplier of Renold Transmission Drive Chains?

– You will purchase 100% genuine Renold conveyor chain products imported directly from the manufacturer by Dai Hong Phat.

– You can have complete peace of mind because Dai Hong Phat will protect you from risks and counterfeit Renold chains.

– Dai Hong Phat will provide CO/CQ documents for the chains to you.

– Renold chain products are always available in Dai Hong Phat’s warehouse, ensuring fast delivery to you.

– Dai Hong Phat will provide technical drawings of the chains you have purchased upon request.

– Dai Hong Phat always provides dedicated support to customers with a team of highly skilled technical experts.

– Dai Hong Phat offers free consultancy on optimizing solutions for your plant’s Renold chain needs.

– Dai Hong Phat will provide the genuine Standard Conveyor Chain catalogue to you.

– You will receive free technical parameter conversion and customization of chain sizes according to your requirements.

– Dai Hong Phat provides nationwide 24/7 delivery, minimizing downtime for your machinery.

– Dai Hong Phat has a professional machining workshop to customize chains according to your specific requirements.

Contact Dai Hong Phat now for consultation!

Or view more information at:

– https://www.khopnoitruc.com/

– https://www.khopkhoatruc.com/

– https://www.facebook.com/khopnoitrucdaihongphat

– https://www.facebook.com/khopkhoatruccondaihongphat

– https://www.youtube.com/channel/UCaWH09QEtoCThHO3uzlfImg

– https://www.youtube.com/channel/UC4LmsXq3FmjtbQaa0cVrXVw

———————————————–

DAI HONG PHAT ENGINEERING SERVICE TRADING MANUFACTURE COMPANY LIMITED

– HCMC Office: 22 Street 11, Khang Dien Residential Area, Duong Dinh Hoi Street, Phuoc Long B Ward, Thu Duc City.

– Ha Noi Office: No. 14-15A, 7th Floor, Charmvit Building, No. 117 Tran Duy Hung, Trung Hoa Ward, Cau Giay District.

– Tel HCM: +84.28.22536631 – 22536632 – 66818587

– Hotline: (+84)906 955 057 | Fax: 028.22536632

– Email: info@dhp-corp.com.vn

– Website: https://www.en.daihongphat.asia/

– Partner website: https://www.renold.com/

| FOR ANY INQUIRIES OR QUOTATION REQUESTS, PLEASE CONTACT: SALES DEPARTMENT HOTLINE: (+84) 0906 955 057 – EMAIL: INFO@DHP-CORP.COM.VN |