Agricultural machinery must operate reliably even in harsh environments. Not only does it require a long drive system lifespan, but it also demands easy maintenance and readily available lubricants. Furthermore, during operation, lubricant loss can damage the soil and contaminate the food chain, so lubricant consumption must be kept low.

With the increasing use of machinery in agriculture, optimizing noise levels and smooth operation in agricultural drive systems is crucial for maximizing total cost of ownership (TCO) and ensuring long-term operational efficiency.

1. Causes of Noise in Agricultural Drive Systems

Noise in agricultural drive systems does not occur randomly but usually stems from specific technical causes:

– Roller chain drives: impact between chain links and sprockets, play in the shaft-hub linkage.

– Cardan shaft drive: torsional vibration, axial misalignment, and requires frequent lubrication.

– Traditional keyway connection: stress concentration, clearance buildup after operating time.

– Oscillating load: characteristic of agricultural machinery when working on uneven terrain.

These factors, combined with a dusty and humid working environment, make the drive system more prone to noise and vibration than other industries.

2. DST Multi-Purpose Fertilizer Spreader – A Typical Example of an Agricultural Drive System

HAWE-Wester’s DST multi-purpose fertilizer spreader is designed for continuous use in dusty environments and under heavy loads. This product line, with capacities ranging from 12 to 34 m³, includes seven types with tandem chassis and three types with tridem chassis. All are suitable for various fertilizer types and are designed for long service life with minimal maintenance costs.

In terms of working principle, manure is fed to the rear of the machine via a squeegee, then distributed by two overlapping spreading rollers before being evenly spread across the field. The squeegee and spreading roller assembly are heavy-duty components, working continuously and requiring a highly reliable drive system that minimizes vibration and noise during operation.

3. Two drive principles for spreading rollers: Roller chain and driveshaft

For the spreading roller assembly on the DST, customers can choose from two different drive principles, each offering a unique optimal solution:

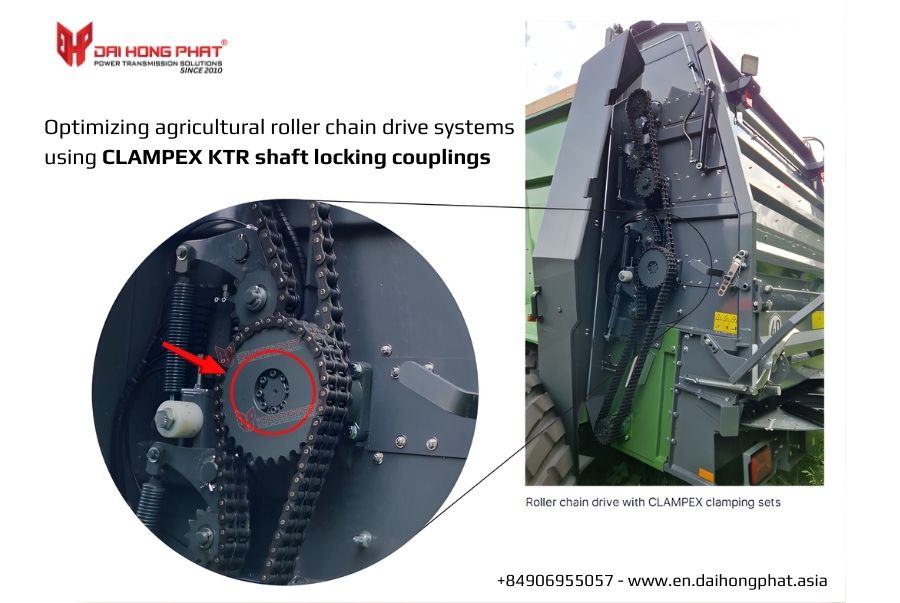

3.1. Optimizing the roller chain agricultural drive system using CLAMPEX shaft locks

Initially, HAWE used tapered couplings according to DIN 6887 standard to connect the shafts and gears in the roller chain drive system. This solution was later replaced with KTR’s CLAMPEX shaft locks.

With a roller chain drive using a Clampex KTR shaft lock, torque is transmitted from the input shaft via gears and chain to the lower spreading roller, then further transmitted to the upper roller via a double gear and a second chain.

This Agricultural Drive Systems has the advantages of simple construction, space saving, and easy installation, and is suitable for many different machine configurations.

However: the chain system requires frequent lubrication and needs to be optimized to reduce wear and noise.

See article: Optimizing roller chain drive systems using CLAMPEX shaft locks.

View product specifications: CLAMPEX KTR clamping sets

3.2. Alternative Solution: Roller drive using a cardan shaft combined with a ROTEX coupling

With this Rotex coupling drive principle, the PTO shaft of the tractor operates the central shaft first, then transmits power to the distribution box, driving the two spreading plates via a cam coupling, central gearbox, and two disc gearboxes.

This alternative solution offers greater safety for the drive system. All drive components are enclosed, and the entire drive system is maintenance-free; no lubrication is required, so lubricants cannot be released into the environment; the angular gears ensure smooth operation at a high level with minimal noise.

> This agricultural drive system is particularly suitable for complex working environments.

See article: ROTEX KTR Elastic Coupling: An Alternative to Driveshafts in Agricultural Machinery

View product specifications: ROTEX Coupling

4. Why do agricultural drive systems need to operate smoothly and quietly?

– Noise is a sign of increased vibration and wear.

– Reducing noise extends lifespan and reduces maintenance costs.

– Smooth operation means high reliability during the growing season.

– Less noise reduces lubrication requirements and is environmentally friendly.

– Smooth operation is the foundation for modern drive solutions.

> For continuously operating equipment such as the DST multi-purpose fertilizer spreader, this requirement becomes even more important and is a core criterion in the design of modern agricultural drive systems.

5. What criteria should businesses prioritize when choosing couplings and shaft linkages?

When choosing a drive solution, don’t just look at the initial purchase price, but evaluate it based on: Noise and smooth operation in agricultural drive systems.

This is an important indicator that directly reflects equipment durability and long-term operating costs. Choosing the right principle for agricultural drive systems is crucial.

—————-/—————–/—————–/—————–/—————–

– Hotline: +84906.955.057 | – Email: info@dhp-corp.com.vn

– Website: https://en.daihongphat.asia/ – https://khopnoitruc.com/ – https://ringfeder.com.vn/

- What is Elastic Shaft Couplings? Applications of Elastic Shaft Couplings

- Structure and Operating Principle of Roflex-SH Shaft Couplings

- Congratulations to Dai Hong Phat Corp for Becoming the Authorized Distributor for KTR Germany in Vietnam

- Outstanding Features of the Bowex M Gear Couplings

- RUBBER ELEMENTS – THE HEART OF THE SHAFT COUPLING